Lab Work on Automation

The aim of the Lab Work on Automation is to give a student an introduction to contemporary automation techniques and to give basic skills of working with them. The Lab Work results in constructing an automated control system based on the programmable logical controller (PLC) for the model of the particle accelerator vacuum system. Obtained experience and skills will be useful for working both at small facilities and benches (students will be able to construct basic automated systems for them) and at large facilities (the Lab Work gives basic knowledge for further studies of more advanced control and automation techniques).

Prerequisites:

- basics of electrical engineering:

- basic parameters: voltage, current (DC and AC), power

- basic devices: power supply, electromagnetic relay, reed switch

- basics of computer networks (IP address, switch, patch-cord)

- basics of computer logic (logical "0" and "1", logical connectives)

Lab Work Structure

|

1. Introduction to automation techniques Programmable logical controllers (PLCs), their types and difference between them and other industrial electronic devices |

|

|

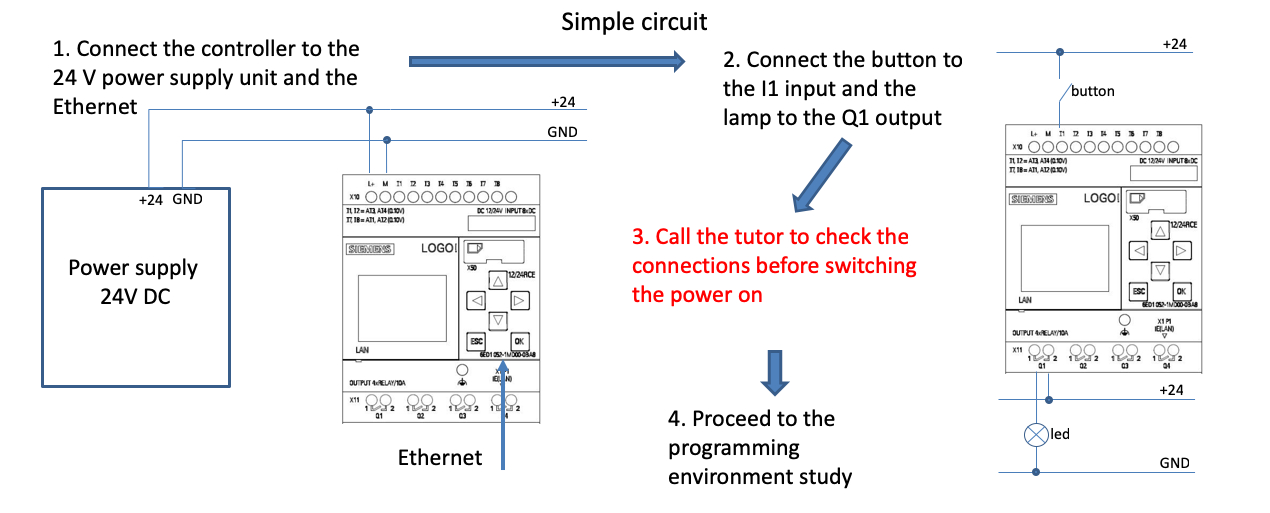

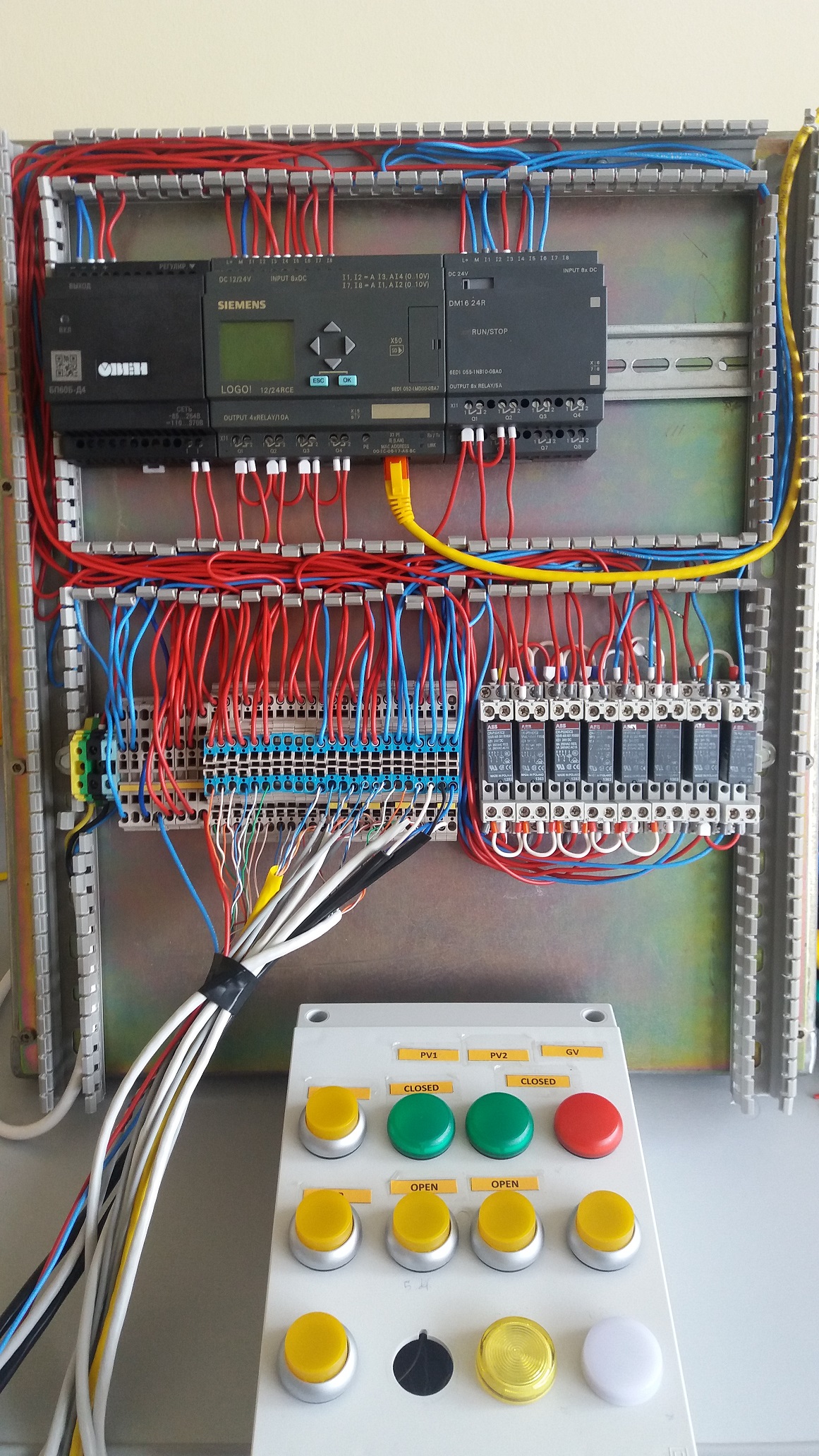

2. Equipment presentation Siemens LOGO! PLC, terminals, relays, control and signal devices. Students assemble a simple circuit. |

|

|

3. Real tasks demonstration Tour to one of the JINR basic facilities with a focus on its control system. |

|

|

4. PLC programming Introduction to the LOGO!Soft Comfort programming environment. Simple examples based on the previously assembled circuit. |

|

|

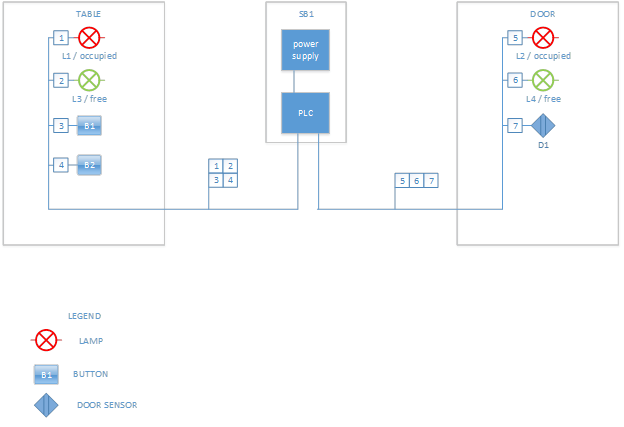

5. Test project Introduction to the automated control systems design through the example of an existing project of the clinic notification system. Assembling, commutation, programming, testing. |

|

|

6. Introduction to the controlled object Lab Work on Vacuum Technology (assembling and pumping, leakage, leak detection). |

|

|

7. Main project Part one: vacuum equipment remote control. |

|